Videos

-

-

A Step Ahead in Intermodal Railroad Equipment 1989

-

A Step Ahead in Intermodal Railroad Equipment 1989 discusses the best use of Maxi-Stack I and Maxi-Stack III double stack container cars. Maxi-Stack I is made for International container traffic with a capacity of 124,000 pounds per well and capability to handle 2 20' containers or one 40' container in the wells and 40', 45' or 48' containers on top. Maxi-Stack III is considered the Terminal Manager's stack car because it can handle a mix of international and domestic containers. With a 48' well it can handle 2 20' containers or a 40' or 48' container in the well and a 40', 45' or 48' container on top. Its well capacity is 117,000 pounds. It's considered a universal double stack car because of its ability to handle any mix of international and domestic containers. Gunderson Engineering uses NASA based finite element analysis to design the double stack container cars and provides skilled craftsmen and excellent workmanship. Greenbrier Intermodal's all Intermodalist expertise and field representatives follow the cars in operation. Customers include APL, BN, CSL Intermodal, Conrail, Intercom, K Line, KCS, sea-Land, SOO, SPRR, TTX and UP.

-

-

Dave Starling and Rick Dorsey Twin Stack Testimonials

-

Various takes of testimonials by Dave Starling of In-Terminal Services and Rick Dorsey of Piggyback Services, intermodal terminal operators of Greenbrier Intermodal's Twin Stack bulkhead double stack container cars 1987., Final takes of Dave Starling were used in "Twin Stack: A Step Ahead in Intermodal Railroading1987.'

-

-

Double Stack A Rail Revolution 1987

-

The double stack container car: a rail revolution, the greatest revolution in transportation since the container ship. Twenty years ago the containership revolutionized sea transportation and now the double stack container car is revolutionizing land transportation.

The BN converted a boxcar yard at the Port of Seattle into a double stack container car train facility (Seattle International Gateway) providing fast efficient movement of containers off vessels onto Twin Stack double stack container trains destined for Chicago and New York. The BN trains provide 3-day service to Chicago and 6-day service to New York. Transit to New York is one third of the time it takes for all water through the Panama Canal.

As a result the traffic at Puget Sound Ports has surged and employment at Gunderson, the Twin Stack manufacturer in Portland, Oregon has been rebirth after the early 1980’s freight car recession. Narrated by Glenn Farley K5TV Seattle. Testimonials by Murray Watson BN, Fred Nolan Freight Shipping Consultant, Jim Smith Locomotive Engineer BN, Cliff Echols Production Supervisor Gunderson, Steve Peterson Welder Gunderson., Narrative by Glenn Farley K5TV. TempoIV TV Monitoring service, Kirkland, WA

-

-

Gunderson in the News 1992 Clark Wood

-

Music video saluting the workforce at Gunderson building double stack container cars. Music by Curtis Salgado & The Stillettos KPTU-12 Portland, OR. KING TV Seattle, KEZT Eugene, KGW Portland. In news of the West, Gunderson employees are saying What Recession? 1980's jobs like this are disappearing into service jobs. The company is in its 7th year and its hiring. Just got an order for 3,000 cars building at 20 cars per day. 1,000 employees and hiring another 100. Note at the start of production the company was building 3 cars per day with less than 200 employees., Clark Wood President Gunderson testimonial and Shawn Martin employee.

-

-

Sea-Land Twin Stack Double Stack Train Service 1985

-

Sea-Land and Southern Pacific Railroad began double stack container car service in 1981 with SPRR cars built by ACF with loads moving from Los Angeles to Houston, Barbours Cut and New Orleans and empty containers returning to Oakland. In 1985 Sea-Land bought its own Twin Stack cars and began double stack container car service from Tacoma and Los Angeles to Chicago and Little Ferry, NJ. This video tracks containers as they move from Yokohama, Japan in S/L's Mariner vessel to Tacoma where they are transferred to Twin Stack trains for movement over the BN to Chicago in 64 hours with continuing 2 day serve to Little Ferry, NY via the NS, D&H and NYSW., Eastern routing over NS to Buffalo, D&H to Binghamton and NYSW to New Jersey results from Conrail Chief Engineer stating that he will not allow double stack container cars on Conrail. Sea-Land officers in the video include Bob Ingram, Gordon Fuller, Mike Collins and Brett Mehlhoff.

-

-

Terminal Operations with Twin Stack 1985

-

In depth discussion of the benefits of cycle loading with Twin Stack double stack container cars at the Port of Tacoma. Cycle loading is a practice where double stack container trains are unloaded and reloaded at the same time increasing productivity and saving labor expenses. Testimonials from John Gray President Intermodal Management Services who operates the Sea-Land Port of Tacoma facility and John Troyke, former CNW Intermodal Executive and current Greenbrier Intermodal field representative in Chicago., At Sea-Land's Port of Tacoma facility, containers are unloaded from vessels originating in Asia and drayed trackside where they are cycle loaded as containers bound for Asia are unloaded. Twin Stack bulkhead double stack container cars are used increasing productivity and saving labor. The Twin Stack cars are built at Gunderson, Portland Oregon and marketed by Greenbrier Intermodal of Walnut Creek, CA. Both Gunderson and Greenbrier Intermodal are owned by The Greenbrier Companies of Lake Oswego, Oregon.

-

-

Twin Stack 1985 A Step Ahead in Intermodal Railroading

-

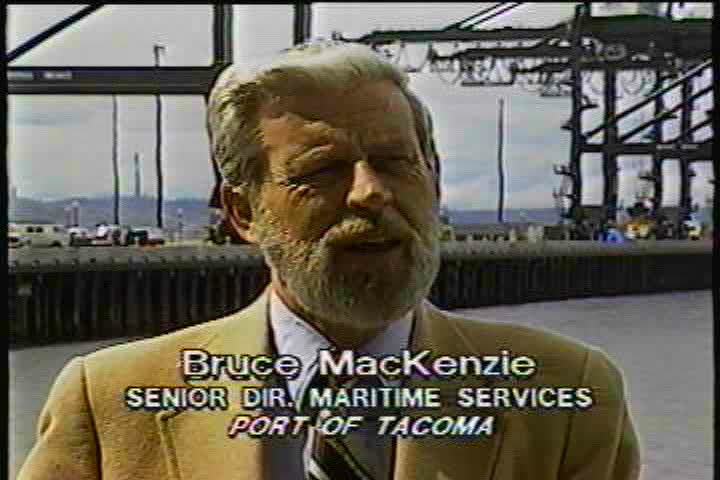

Twin Stack A Step Ahead in Intermodal Railroading combines Gunderson's Engineering and Manufacturing Expertise with Greenbrier Intermodal's Intermodal Operating Expertise and Courage and Greenbrier's Financial Capability to provide the railroad industry with revolutionary double stack container cars for international and domestic traffic., The video features Chuck Anderson Production Manager Gunderson, Bill Galbraith Sales Gunderson, Gordy Rains Engineering Gunderson, Bruce McKenzie and Ike Morrow Port of Tacoma.

-

-

Twin Stack II 1987 A Step Ahead in Intermodal Railroading

-

Twin Stack double stack container car train service and terminal operations featuring cars built by Gunderson and marketed by Greenbrier Intermodal. Trains operated by Sea-Land, BN, SPRR, ATSF and SOO Line. Sea-Land Twin Stack trains loading at Port of Tacoma by Intermodal Management Services, John Gray President and testimonials by Dave Starling VP Intermodal In-Terminal Services and Ike Morrow Port of Tacoma. Gunderson Engineering represented by Gary Kaleta and Roger Hawkins and Greenbrier Intermodal by Dennis Purdy, LA field representative. BN Innovative Intermodal Service and ATSF Econo-Stack. Customers include Sea-Land, BN, SPRR, ATSF, SOO, CSX, Conrail and TTX. U.S. DOT states that double stack container cars are the most important development in Intermodal transportation since containerization., The state of double stack container car technology in 1987, articulated cars with 100 ton intermediate trucks with well capacity in the 90,000 pounds to 100,000 pounds range. In 1988 the industry moves to 125 ton intermediate trucks with well capacity rising to 124,000 pounds greatly reducing overloads.